Rebar is commonly a fundamental steel bar or block that is greatly utilised in bolstered concrete and strengthened masonry buildings. These rebars are frequently created from carbon steel and may be recounted as reinforcing steel Or maybe reinforcement. Underneath Structural BIM Solutions Rebar detailing can be a willpower of making fabrication or store drawings of steel reinforcement for that development course of action. The site fabrication drawings which can be produced determined by structure drawings for reinforcing steel are Rebar Comprehensive drawings. Engineers and Architects make structure drawings to think of the desired strengths based on the rebar detailing that offers diameter, bar styles, quantities, degree of bars to facilitate your website for preventing delays and wastage thereby dashing the whole construction system.

Each rebar is in-depth symbolizing a form, size, and diameter Based on the necessities within the design and style drawing. The Rebar placement is then demonstrated in additional detail which signifies the concrete cover, exact location, and Distinctive approach to placement if wanted. The rebar particulars and bar bending schedules will display bar diameter, bar notation, the quantity of bars, excess weight Along with the bars, and length of Just about every bar as well as mentioning the overall pounds on the overall team of bars put in the drawing. Throughout the planning of rebar specifics, the stock lengths of bars are held in check out to make certain there is not any wastage with the material.

Rebar Detailing and Reinforcement concrete detailing is often modeled and coded in three-dimension utilizing the 3D Modelling technologies like BIM Modelling Companies. The specialised rebar detailing computer software like Rebar CAD and AutoCAD handy for this goal might assist each member of your structural engineering to organize designs, document, track, whilst All round Command.

Possessing recognized basic principle Idea of rebar detailing an area of structural BIM modeling, permit us to attempt to begin to see the relevance of it in the overall design course of action is. Some inside the factors are:

Great importance of Rebar detailing in Structural BIM Modeling

When second drawings and bending schedules are more likely to be developed and specified, the 3D model is Also issued to Everybody they users commencing from the consulting engineer and contractor departments right down to the steel fixers that happen to be at the stroll-out on-internet site. The mixture of These two develop into Particularly useful for internet site staff where site limitations or congestion of reinforcements stay unknown until finally you can find reinforcement and fixation on-website page. For each bar, the precise posture of fixing is revealed within 3D model along with any hindrances or obstructions.

Developing detailing reinforcements in 3D over the 2nd system is not just faster but modeling rebar inside a three-dimensional natural environment allows take out clashes. Though modeling you can maybe visualize if any in the bars tend not to correct in a very determined place, therefore recognize these kinds of clashes within the rebar drawings. There's Probably the facility to analyze the reinforcement in entire depth as becoming a precise detail representation in advance of it is becoming purchased in the fabricator and complicated cages are assembled off-website.

When There exists a right rebar detailing solution readily available, a powerful and correct reinforcement model can be achieved by importing structural calculations from the structural Evaluation plan. With Automation involved modifications tend to be reflected inside the 3D rebar detailing along with necessary updates to drawings and schedules swiftly when improvements are created somewhere else in contrast to possessing to carry out guide adjustments to second sections and views.

In place of based on manual enter from paper schedules, the rebar fabricator can extract details directly from your product towards the equipment. The concrete pours is often effectively-defined throughout the model to specifics like quantities and volumes To make certain more accuracy in controlling product deliveries. This allows higher Handle and provide about significantly less wastage and reduction of General costs.

Getting 3D detailed digital types get more info will not likely prohibit the advantage to some one-stage that way from the engineering and detailing period but may be applied while in the phases. Obtaining reinforcement fully modeled in 3D, the contractor is certain that it is going to simply fit in locations when the time will come it being preset on-website. The information from the model is often utilised within the discipline enabling contractors to conduct a model-based format by using robotic total station devices as well as tracking rebar and resources and pinpointing when and where by they're going to be expected.

Fixers existing on-web-site appears to be in the model ecosystem towards the rebar detailing to accurately understand its application, i.e. precisely what is expected where and when instead of counting on their interpretation of common 2D drawings.

The structural engineers can undoubtedly plus much more rapidly produce design and style studies, schedules, and drawings in the 3D product when compared to second designs, therefore enhancing design efficiency. There is additional precision in price projection based upon the rebar portions created while in the 3D model as They can be a lot more dependable instead of 2nd drawing choose-offs. Not just this the portions are fully traceable, enabling comparisons and checks to become done very easily.

Using these factors, we could conclude that Rebar Detailing a self-discipline of Structural BIM Modelling Solutions is but a single in the important requirements towards the overall accomplishment with the venture daily life cycle. To summarize, having Rebar Detailing the rebar contractor can goal making rebars there will not be any should estimate reinforcement prerequisites for procurements at the Online page due to productive 3D designs. The product will depict the necessity for anchors and laps inside the drawings thereby guaranteeing design and style adequacy In combination with reducing wastage. The overall squander and time delays are reduced at the location since just about every one of the shape drawings are typically available. According to this info the bars may be conveniently fabricated In accordance with the shapes and number of bars necessary.

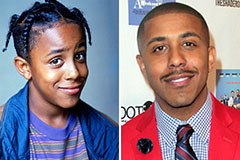

Marques Houston Then & Now!

Marques Houston Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now! Bernadette Peters Then & Now!

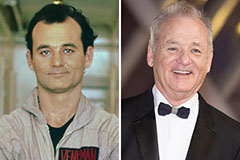

Bernadette Peters Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now!